Fourslide Stamping

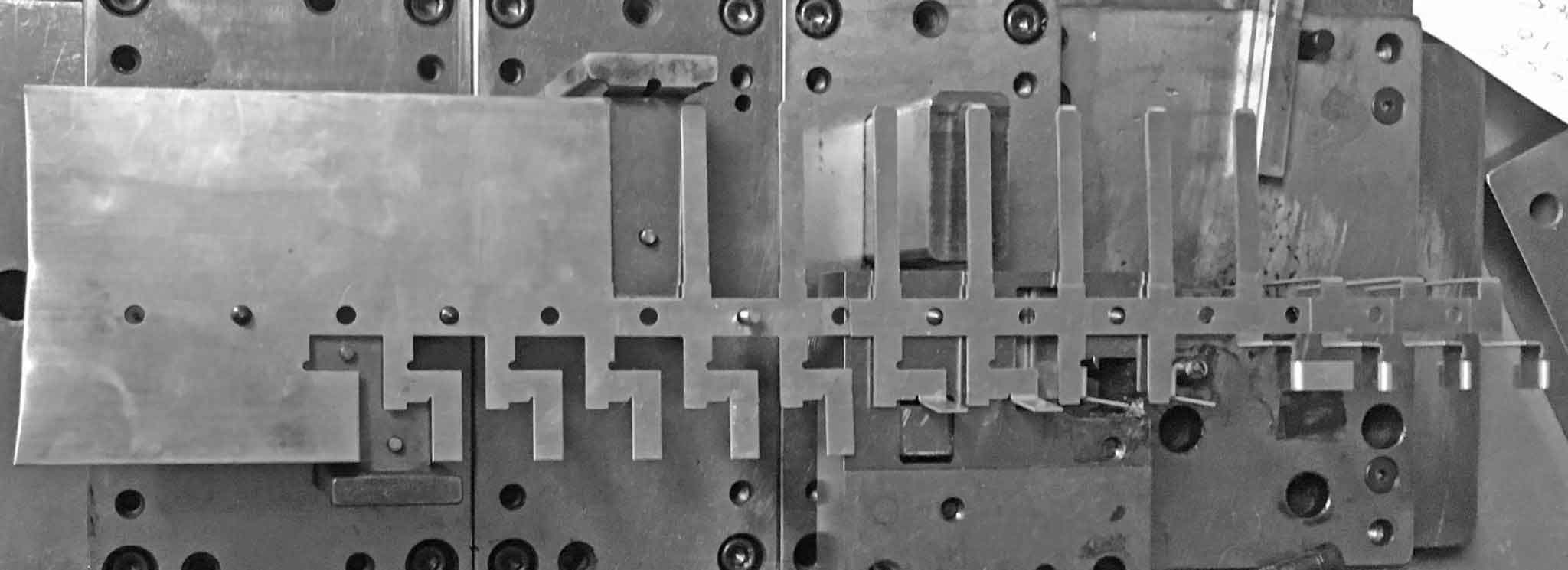

India Metal Parts’s comprehensive fourslide stamping and multi-slide metal stamping capabilities allow us to fulfill your sourcing needs for parts made from either flat strip stock or wire. Our equipment can handle strip stock material from as thin as .002” up to .093” thick. Round, square or shaped wire capabilities range between .010” through .187”.

Benefits of Fourslide Stamping and Multi-Slide Stamping

A lower tooling investment, compared to other methods, and the rate at which high quality, close tolerance parts can be produced, equals lower costs and a fast turnaround for you. Production runs from a few thousand to millions are easily handled both on the production floor and in our production management processes. Additionally, working in three planes, fourslide and multi-slide metal stamping can lead to fewer design constraints on a single component, which may offer your design team the benefit of combining two parts into one. To achieve that end, better than half of our fourslide stamping machines already incorporate a progressive die stamping section that gets used in conjunction with the forming tooling.

That’s not all, our ability to incorporate in-die insertion of electrical contacts, rivets, PEMTM Fasteners and screws, as well as thread tapping, spot welding, and other two-stage tooling can eliminate secondary operations, lowering your total component costs even further. Although not appropriate for all parts, your part may benefit from the cost saving advantages offered by fourslide stamping and multi-slide stamping methods.

How can fourslide stamping help you?

Please visit our Secondary Operations & Assemblies and Value-Added Services pages to learn how we can customize an assembly and consignment solution to meet your needs.

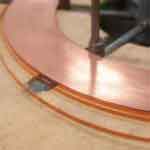

Materials for Function & Performance

Selecting the right materials is critical to the success of your part. Offering you the expert advice you’re looking for, India Metal Parts’s experience with a vast array of materials makes your search for component sourcing a trouble-free experience. All of the copper-based materials, steels in low carbon, high carbon and stainless steel alloys, as well as performance-specific nickels, aluminum, palladium and clad/bimetallic strips are available.

Case Study: How India Metal Parts simplified a customer’s process by 50%

Is Fourslide Stamping Right for your Part?

Email Us to learn the best way to have your part manufactured. Once we see the design and the dimensions, we’ll know what’s needed to get you the results you’re after.